In a groundbreaking study published in the *Journal of Materials Research and Technology* (known in English as the *Journal of Materials Research and Technology*), researchers have unveiled a novel approach to laser metal additive manufacturing that could revolutionize the energy sector. The study, led by Fuxiang Li of the State Key Laboratory of Advanced Processing and Recycling Non-ferrous Metals at Lanzhou University of Technology, explores the potential of hot wire-laser metal deposition (HW-LMD) for fabricating super martensitic stainless steel (SMSS), a material critical for high-performance applications in oil and gas, as well as renewable energy infrastructure.

Traditional cold wire-laser metal deposition (CW-LMD) has long been plagued by limitations in deposition efficiency and heat input, which can compromise the mechanical properties of the final product. Li and his team set out to address these challenges by investigating the HW-LMD process, which introduces heat directly to the wire feedstock, allowing for more precise control over the deposition process. “By refining the microstructure of SMSS through HW-LMD, we’ve been able to achieve a significant improvement in the material’s strength-toughness balance,” Li explained. “This could have profound implications for the durability and performance of components used in harsh environments, such as subsea pipelines and offshore wind turbines.”

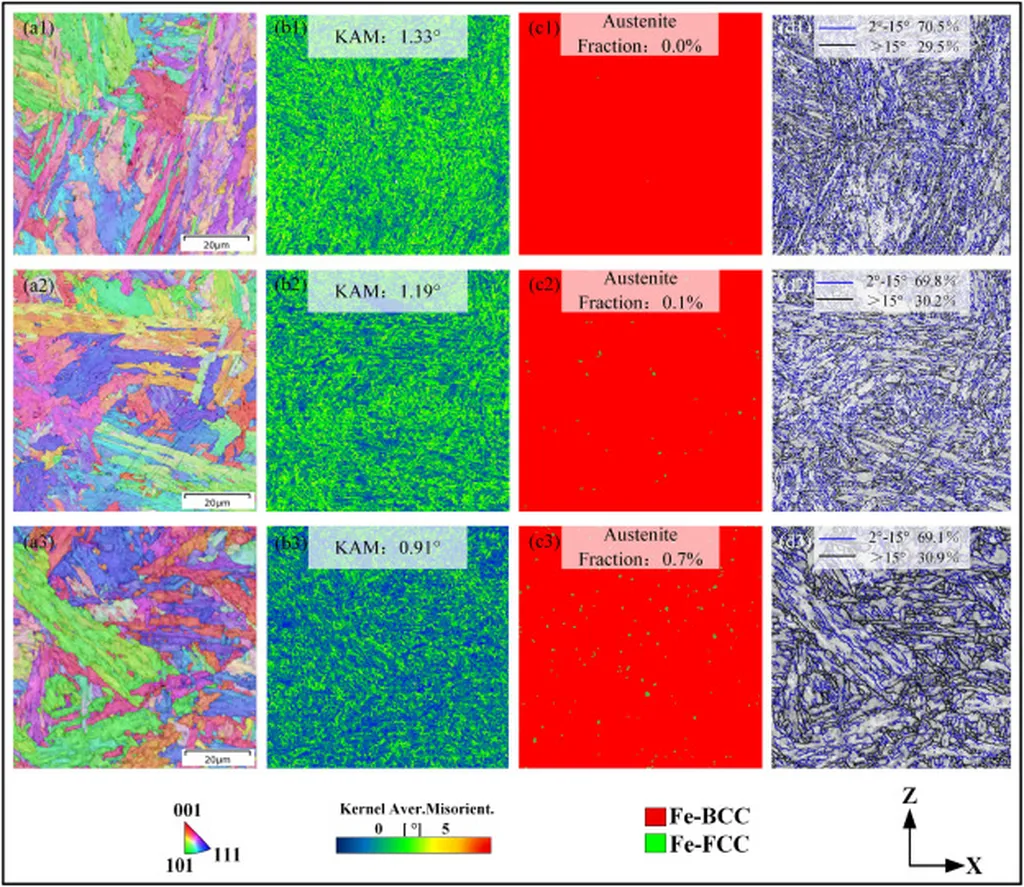

The study’s findings are indeed compelling. Compared to CW-LMD, HW-LMD reduces martensite grain size by 30.4% to 43.1%, leading to a more uniform and refined microstructure. This refinement translates into lower kernel average misorientation (KAM) values, indicating reduced lattice distortion and improved material integrity. While the average hardness and tensile strength of HW-LMD samples were marginally lower than those of CW-LMD, the ductility saw a notable improvement, with a maximum elongation of 20.7%.

For the energy sector, these advancements could be a game-changer. SMSS is widely used in applications requiring high strength, corrosion resistance, and toughness, such as pipelines, pressure vessels, and structural components in offshore environments. The enhanced ductility and refined microstructure achieved through HW-LMD could lead to longer-lasting, more reliable components, reducing maintenance costs and improving safety.

The commercial impact of this research is not lost on industry experts. “The ability to optimize the strength-toughness balance in SMSS through advanced manufacturing techniques like HW-LMD opens up new possibilities for designing and fabricating components that can withstand extreme conditions,” said a senior materials engineer at a leading energy company. “This could accelerate the adoption of SMSS in critical applications, enhancing the overall efficiency and reliability of energy infrastructure.”

Looking ahead, the research team plans to further explore the potential of HW-LMD for other high-performance materials and applications. “Our goal is to push the boundaries of additive manufacturing technologies to enable the next generation of energy solutions,” Li stated. “By continuing to refine our processes and materials, we can contribute to a more sustainable and resilient energy future.”

As the energy sector continues to evolve, innovations in materials science and manufacturing technologies will play a pivotal role in shaping its trajectory. The work of Li and his team, published in the *Journal of Materials Research and Technology*, offers a glimpse into the exciting possibilities that lie ahead, promising to transform the way we design, fabricate, and deploy critical components in the energy landscape.