In the heart of China’s coal mining industry, a groundbreaking study led by Guangzhong Ji from the School of Earth and Environment at Anhui University of Science and Technology is set to revolutionize the way coal thickness is predicted in working faces. Published in the esteemed journal *Meitan xuebao* (translated to *Coal Science and Technology*), Ji’s research on 3D frequency dispersion inverse imaging of channel waves promises to significantly enhance the accuracy of coal thickness prediction, a critical factor for the energy sector.

The current methods for inverting coal thickness through channel wave dispersion have been relying on a single frequency for velocity CT tomography imaging, often leading to inaccuracies. Ji’s innovative approach, however, calculates the channel wave dispersion curve of a multi-layer elastic medium model and employs a three-dimensional dispersion inversion method. This method was verified through forward simulation, demonstrating its effectiveness in improving prediction accuracy.

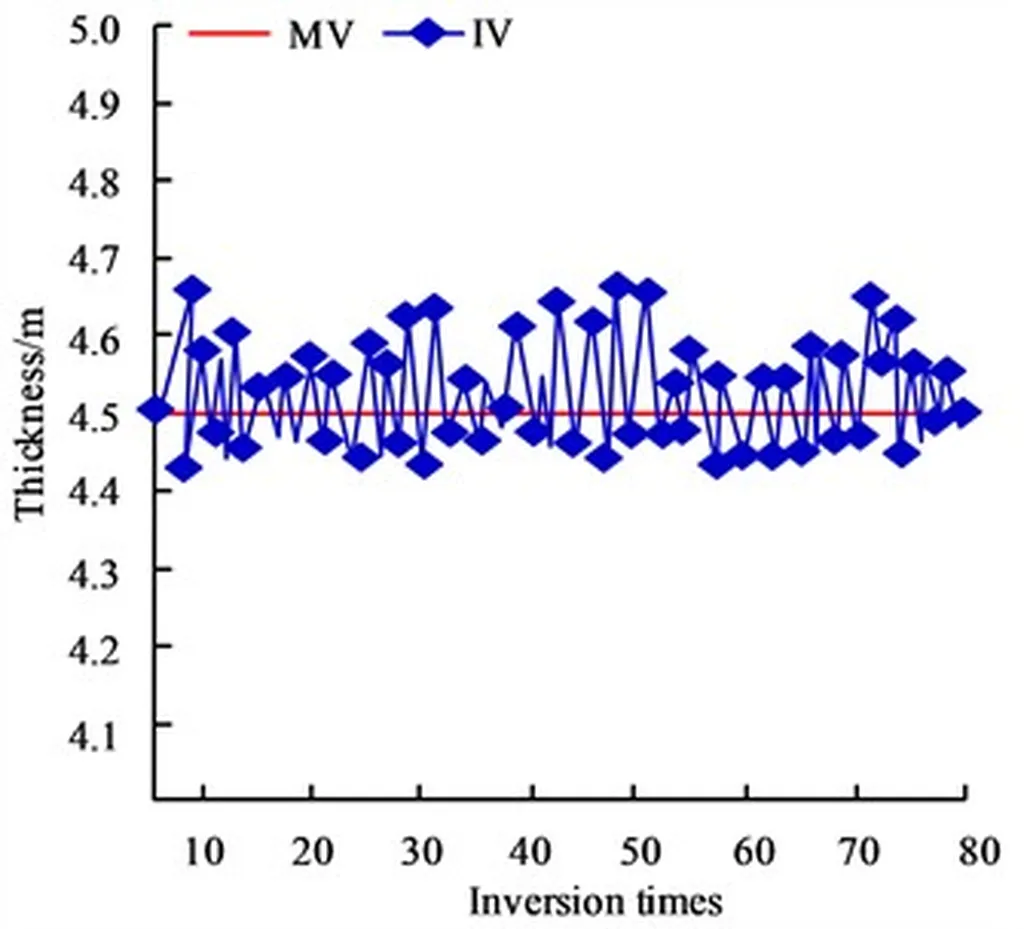

“The three-dimensional dispersion inversion of channel waves improves the accuracy of coal thickness prediction in coal seam working faces,” Ji explained. “Compared with the coal thickness exposed in the roadway, the average fitting error is only 0.22 m. This level of precision is a game-changer for the industry.”

The process involves extracting the dispersion curve of the Love channel wave in the actual coal seam using the generalized S-transform. Tomographic imaging of the working face is then performed by setting the frequency range and step size, resulting in velocity CT imaging maps at different frequencies. The working face is divided into several sections, and the dispersion curves of each section are calculated based on the results of tomographic imaging. The dispersion curves of each section are inverted, and the velocity distribution and coal thickness distribution of the entire working face are obtained by integrating the inversion results.

Ji’s research employs nonlinear global optimization algorithms such as genetic algorithms, pattern search algorithms, particle swarm optimization algorithms, and simulated annealing algorithms. These algorithms are more likely to find the global optimal solution, thereby improving the accuracy of coal thickness inversion.

The practical implications of this research are profound. Accurate prediction of coal thickness is crucial for efficient mining operations, safety management, and resource planning. By enhancing the precision of coal thickness prediction, Ji’s method can lead to more efficient extraction processes, reduced operational costs, and improved safety standards.

“This technology has a relatively high accuracy in the prediction of coal thickness in the working face,” Ji noted. “It’s a significant step forward for the energy sector, particularly in coal mining, where precision and efficiency are paramount.”

As the energy sector continues to evolve, the need for advanced technologies that enhance operational efficiency and safety becomes increasingly critical. Ji’s research on 3D frequency dispersion inverse imaging of channel waves represents a significant advancement in this field, offering a promising solution for the challenges faced by the coal mining industry.

The study, published in *Meitan xuebao*, underscores the importance of continuous innovation and research in the energy sector. As the world grapples with the complexities of energy production and consumption, such advancements are essential for shaping a more sustainable and efficient future.

In the words of Guangzhong Ji, “This research is not just about improving accuracy; it’s about transforming the way we approach coal mining and resource management. It’s about paving the way for a more efficient and safer future in the energy sector.”