In the relentless pursuit of efficiency and cost reduction in the mining and construction industries, a groundbreaking study has emerged that could redefine the way we approach material crushing. Yevhen Mishchuk, a researcher from the Kyiv National University of Civil Engineering and Architecture, has delved into the intricate workings of vertical shaft impact (VSI) crushers, offering insights that promise to optimize energy consumption and enhance productivity.

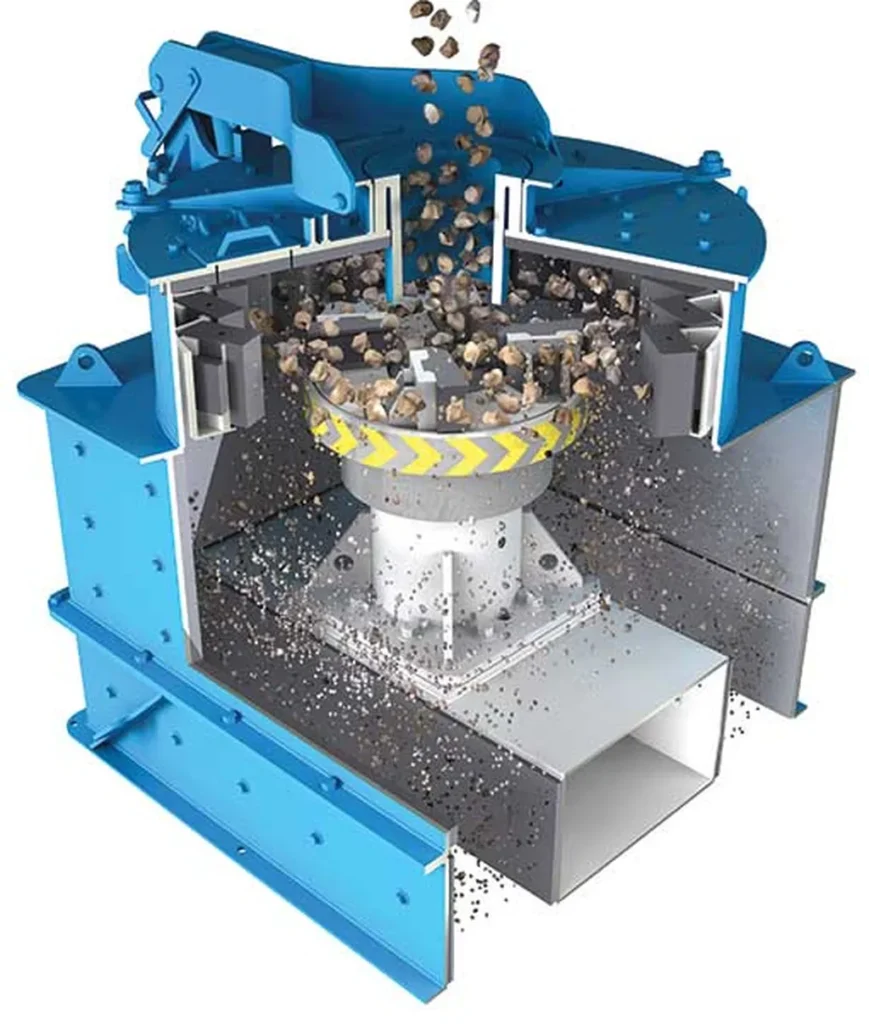

Vertical shaft impact crushers, or VSI crushers, are known for their ability to produce high-quality cubical shaped aggregates. However, their energy efficiency and productivity have always been areas ripe for improvement. Mishchuk’s research, published in the journal “Mining, Construction, Road and Melioration Machines” (translated from Ukrainian), focuses on the critical speed of particles as they exit the rotor, a factor that significantly influences the crusher’s performance.

“The critical speed of particles is a pivotal factor that determines the efficiency of the crushing process,” Mishchuk explains. “By understanding and controlling this speed, we can optimize the energy consumption and productivity of VSI crushers.”

Mishchuk’s study analyzes the equations of motion for particles within the crusher and investigates how the physical and mechanical properties of materials affect the critical exit speed of particles. This research provides a deeper understanding of the dynamics involved in the crushing process, paving the way for more efficient and cost-effective operations.

One of the key findings of the study is the relationship between the rotor’s linear speed and the crushing effect. Mishchuk’s work shows that increasing the linear speed of the rotor enhances the impact effect, allowing for the crushing of even the toughest materials with relatively low energy consumption. This is a significant breakthrough, as it directly addresses the energy costs that have long been a burden on companies in the construction materials sector.

Moreover, the study highlights the importance of the free-fall crushing principle, which ensures a uniform impact on each particle. This not only prevents over-crushing but also reduces the amount of dust fraction, a common issue in traditional crushing methods. “The free-fall crushing principle is a game-changer,” Mishchuk notes. “It ensures that each particle is treated uniformly, leading to a more consistent and higher-quality product.”

The implications of Mishchuk’s research are far-reaching. By optimizing the critical speed of particles and understanding the dynamics of the crushing process, companies can significantly reduce their energy consumption and operational costs. This is particularly relevant in the current economic climate, where energy costs are a major concern for many industries.

Furthermore, the insights gained from this research can guide the development of more advanced and efficient crushing technologies. As the demand for high-quality aggregates continues to grow, the need for more efficient and sustainable crushing methods becomes increasingly important. Mishchuk’s work provides a solid foundation for future innovations in this field.

In conclusion, Yevhen Mishchuk’s research offers a fresh perspective on the optimization of vertical shaft impact crushers. By focusing on the critical speed of particles and the dynamics of the crushing process, Mishchuk has provided valuable insights that can lead to more efficient and cost-effective operations. As the industry continues to evolve, this research will undoubtedly play a crucial role in shaping the future of material crushing technologies.