In the heart of Kazakhstan, a groundbreaking system is revolutionizing the way we monitor and maintain the safety of mining operations. Viktoriya V. Kazantseva, a researcher from Abylkas Saginov Karaganda Technical University, has developed a complex system of geotechnical monitoring that is setting new standards in the industry. This innovative approach, tested at the “Edelweiss +” open-pit coal mine, integrates multiple monitoring methods to provide comprehensive insights into deformation processes, ensuring the safety and efficiency of mining operations.

The system is a multi-stage process that begins with the analysis of archive satellite images to identify areas of significant surface displacements. “The first stage is crucial as it sets the foundation for our monitoring efforts,” explains Kazantseva. “By analyzing historical data, we can pinpoint areas that require immediate attention and further investigation.”

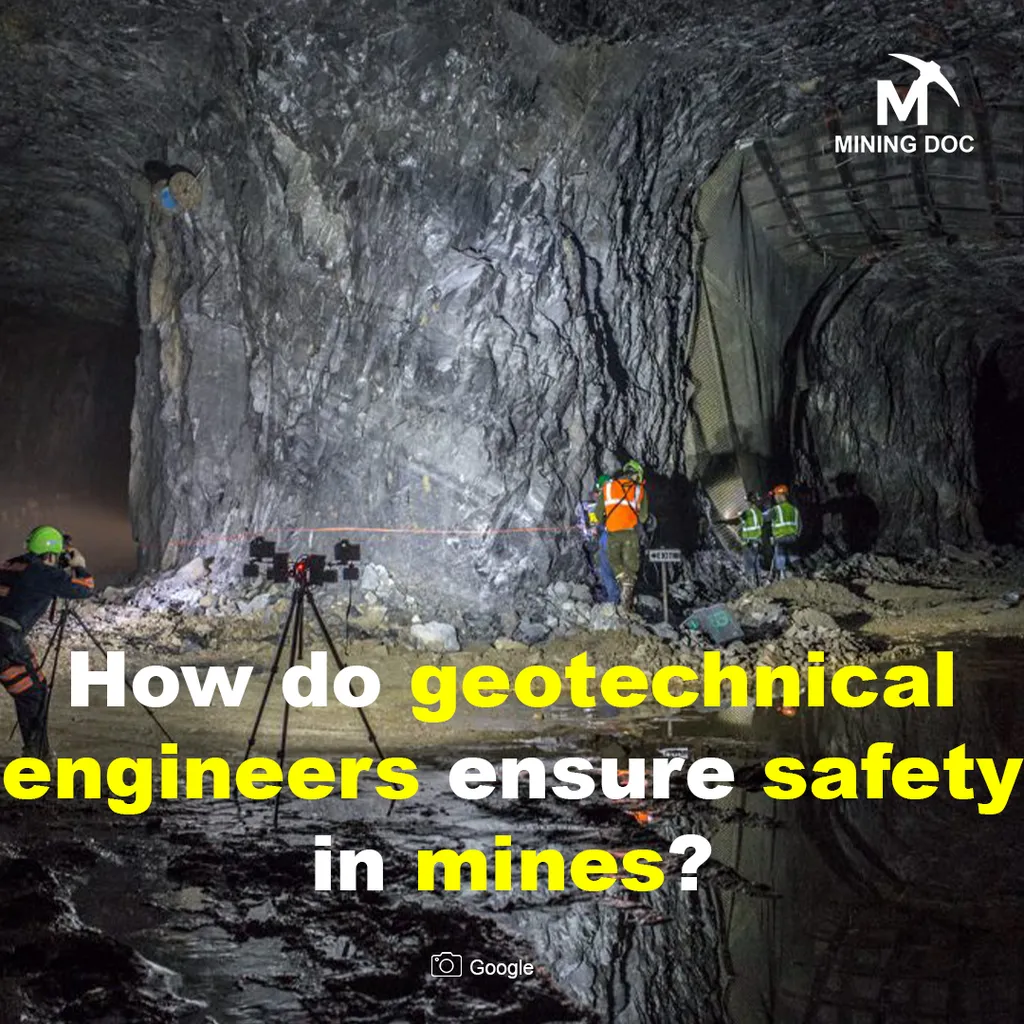

The second stage involves aerial photography using unmanned aerial vehicles (UAVs) to create detailed 3D models of surface areas with deformations. These models provide a visual representation of the terrain, allowing for precise analysis of deformation processes. “The use of UAVs has been a game-changer,” says Kazantseva. “It allows us to capture high-resolution images and create accurate 3D models, which are essential for understanding the dynamics of deformation.”

The third stage includes the creation of a geomechanical monitoring system based on instrumental observation methods in areas with critical changes. This involves the use of electronic tacheometry and GNSS measurements to clarify the type and dynamics of deformations of the rock mass. “Instrumental observations provide us with real-time data, which is crucial for making informed decisions and taking timely actions,” Kazantseva explains.

The final stage is the creation and updating of a geospatial database that provides continuous monitoring of the object’s condition. This database integrates all the data collected from the previous stages, allowing for a holistic analysis of the deformation processes. “The geospatial database is the backbone of our system,” says Kazantseva. “It allows us to monitor the condition of the object continuously, ensuring the safety and efficiency of mining operations.”

The results of the testing of the geotechnical monitoring system based on Sentinel-1 and TerraSAR-X/TanDEM-X satellite images were impressive. Surface subsidence of up to 25 mm was detected on the northern side of the “Edelweiss +” open-pit mine. Aerial photography of the open-pit mine allowed for the construction of digital 3D models of the terrain, the comparison of which confirmed deformation processes at the +556 m horizon. Instrumental observations using modern geodetic methods clarified the type and dynamics of deformations of the rock mass.

The integration of geospatial data in the geotechnical monitoring system ensures prompt detection of deformations, their analysis and forecast, which allows us to minimize the risks of destruction and increase the safety of operation of technogenic objects. This system has significant implications for the energy sector, particularly in the mining industry. By providing accurate and timely data on deformation processes, it enables mining companies to take proactive measures to prevent accidents and ensure the safety of their operations.

The research was published in the journal ‘Записки Горного института’, which translates to ‘Notes of the Mining Institute’. This publication is a testament to the significance of Kazantseva’s work and its potential to shape the future of geotechnical monitoring in the mining industry.

As the energy sector continues to evolve, the need for accurate and reliable monitoring systems will only grow. Kazantseva’s research provides a promising solution to this challenge, offering a comprehensive and integrated approach to geotechnical monitoring. By leveraging the power of geospatial data, UAVs, and instrumental observation methods, this system is poised to set new standards in the industry and pave the way for safer and more efficient mining operations.