In a groundbreaking development that could reshape the energy sector, researchers have discovered a novel method to enhance the performance of sintered Nd–Fe–B magnets, the workhorses of modern green technologies. The study, led by Ma Liguo, explores the impact of grain boundary diffusion using sputtered Dy70Cu15Ga15 alloys, offering a significant boost in coercivity— the material’s resistance to demagnetization—without compromising its magnetic strength or energy product.

Ma Liguo, whose affiliation details are not provided, explains, “The grain boundary diffusion treatment can significantly improve the coercivity of the magnets, increasing it by 22.7% from 15.86 kOe to 19.46 kOe.” This enhancement is a game-changer for industries relying on high-performance magnets, such as electric vehicles, wind turbines, and various renewable energy technologies. The improved coercivity means these magnets can operate more efficiently in harsh conditions, reducing energy losses and extending the lifespan of critical components.

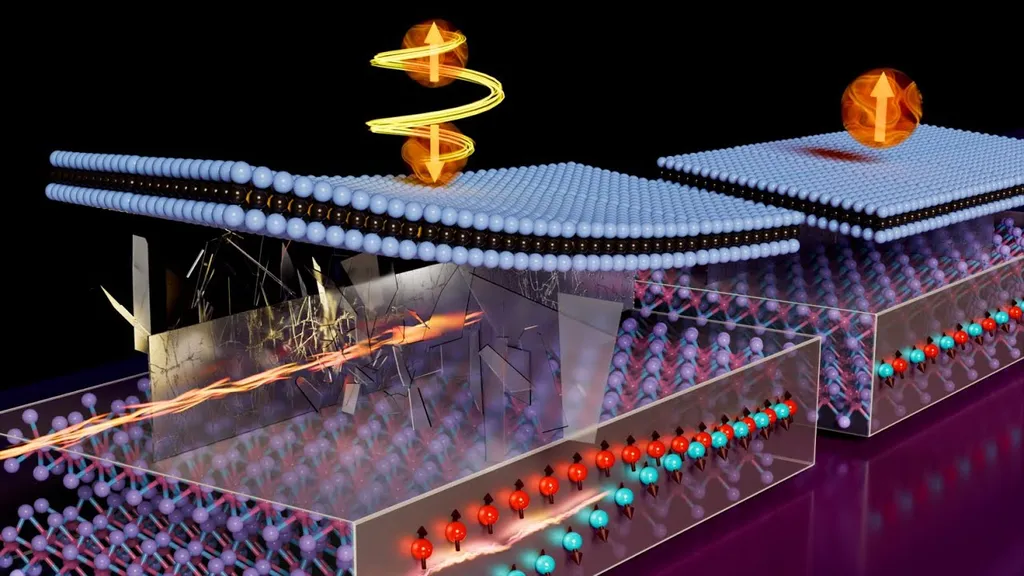

The research, published in *Fenmo yejin jishu* (translated to *Rare Metal Materials and Engineering*), delves into the microstructural changes induced by the diffusion process. Dy, a rare earth element, diffuses into the grain boundaries, optimizing their distribution and replacing Nd in the main phases to form (Nd,Dy)2Fe14B phases. This substitution enhances the anisotropic field of the defect layer, suppressing the nucleation of demagnetized domains. Additionally, the eutectic diffusion of CuGa alloys with low melting points opens up diffusion channels, improving the efficiency of Dy diffusion and optimizing the grain boundary structure.

One of the most compelling aspects of this research is its potential to improve corrosion resistance. The Dy-rich rare earth phases formed at the grain boundary are more stable and have a higher corrosion potential. This means the magnets are less likely to degrade in corrosive environments, a critical factor for applications in marine and offshore wind energy sectors.

The study also reveals that the X-ray diffraction peaks of the main phases shift toward larger angles after the grain boundary diffusion, indicating better grain orientation. This improvement could lead to more efficient and powerful magnets, further driving advancements in energy technologies.

The implications of this research are far-reaching. As the world transitions to cleaner energy sources, the demand for high-performance magnets is soaring. The ability to enhance the coercivity and corrosion resistance of sintered Nd–Fe–B magnets could revolutionize the energy sector, making renewable energy technologies more reliable and cost-effective.

Ma Liguo’s work highlights the importance of innovative materials science in addressing global energy challenges. By pushing the boundaries of what is possible with magnet technology, researchers are paving the way for a more sustainable future. As the energy sector continues to evolve, the insights gained from this study could shape the development of next-generation magnets, driving progress in green technologies and beyond.

In a world increasingly focused on sustainability and efficiency, this research offers a promising path forward, demonstrating the transformative power of scientific innovation.