In the quest for green energy solutions, hydrogen has emerged as a promising contender, and a recent study led by Junshi Zhang from Beihang University’s School of Transportation Science and Engineering is shedding new light on optimizing its production. The research, published in the Journal of Engineering Science, delves into the challenges and solutions for controlling hydrogen penetration in alkaline water electrolysis (AWE) systems, a critical process for green hydrogen production.

Alkaline water electrolysis is a mature and cost-effective technology for producing hydrogen, but it faces a significant hurdle: hydrogen to oxygen (HTO) penetration. This phenomenon occurs when hydrogen gas produced at the cathode crosses over to the anode side, mixing with oxygen. This not only compromises system safety but also triggers frequent shutdowns, hampering production efficiency. “The problem of HTO penetration is a key factor restricting the safety and efficiency improvement of AWE technology,” Zhang explains.

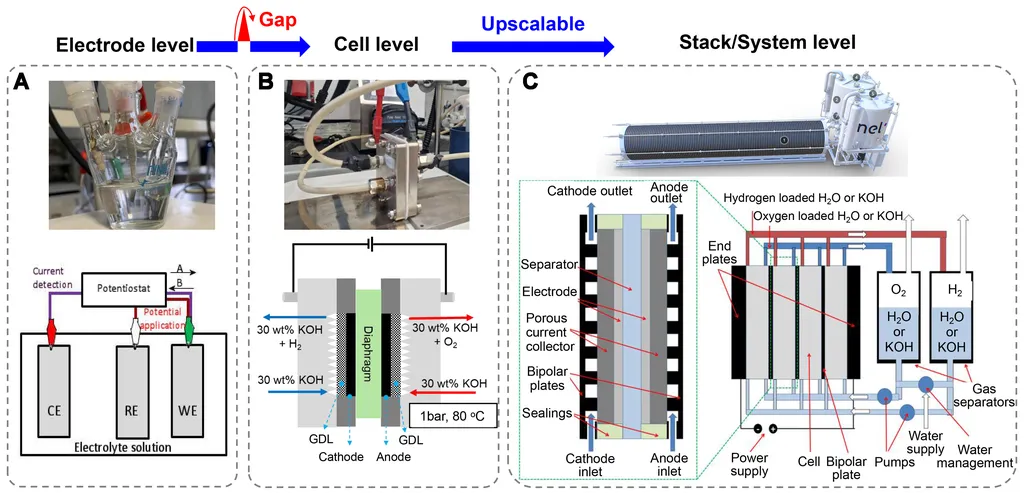

The study provides a comprehensive review of the formation mechanisms and influencing factors of HTO, highlighting the dominant role of the lye mixing cycle. By establishing mathematical models and conducting experimental verification, the researchers analyzed how various parameters such as current density, system pressure, working temperature, alkali concentration, and alkali flow rate affect HTO concentration. Their findings reveal that increasing current density, decreasing system pressure and operating temperature, and increasing alkali concentration all help reduce HTO concentration.

However, practical applications require a balanced approach. “Adjustment of these parameters is often constrained by multiple factors, so it needs to be considered comprehensively to develop an optimal control strategy,” Zhang notes. The research explores various control methods, including advancements in diaphragm materials, catalyst optimization, and structural improvements in electrolytic cells. Notably, the introduction of a functional thin interlayer between the electrode and the diaphragm, and the use of ultrasound or a magnetic field to promote bubble detachment, have shown promising results.

One of the most effective methods identified is the lye separation cycle technique. By separating the cathode and anode cycling lye, the cross penetration of hydrogen can be significantly reduced. Although this technique faces challenges such as imbalance of lye concentration, strategic solutions like switching cycle modes regularly can mitigate these issues, ensuring stable system operation.

The implications of this research for the energy sector are substantial. As the world shifts towards sustainable energy solutions, the optimization of hydrogen production technologies becomes increasingly crucial. “Future research should continue to explore efficient, low-cost, and easy-to-engineer HTO control strategies,” Zhang suggests, pointing towards the integration of artificial intelligence and machine learning for accurate modeling and predictive control of electrolytic systems.

The study also underscores the importance of developing new diaphragm materials and efficient catalysts, which could further enhance the safety and efficiency of hydrogen production. By addressing the HTO penetration problem, this research paves the way for more reliable and cost-effective hydrogen production, supporting the growth of the hydrogen energy industry.

As the global demand for green energy continues to rise, innovations in hydrogen production technology will play a pivotal role in shaping the future of the energy sector. With ongoing research and development, the vision of a sustainable hydrogen economy is becoming increasingly attainable.