In the heart of Xinjiang, a high-altitude, cold-region open-pit metal mine is not just digging for ore; it’s unearthing a new approach to carbon accounting and decarbonization that could reshape the mining industry’s future. This groundbreaking research, led by Guiqi Li from the Center for Rock Instability and Seismicity Research at Northeastern University in Shenyang, China, and published in the Journal of Engineering Science, is a beacon of innovation in the face of global climate change and the urgent “dual carbon” goals of peaking carbon emissions and achieving carbon neutrality.

The mining industry, known for its high energy consumption and substantial emissions, is under significant pressure to transition to low-carbon operations. However, high-altitude and cold-region mines face unique challenges. “Low-temperature and low-pressure environments significantly reduce fuel combustion efficiency, blasting performance, and equipment productivity,” explains Li. This results in increased energy consumption and carbon emission intensity compared to conventional mining regions.

To tackle these issues, Li and his team adopted a life cycle assessment framework to systematically identify emission sources across the entire production process. They developed a multifactor-coupled carbon emissions accounting model that integrates high-altitude environmental conditions, equipment performance metrics, mining design parameters, and carbon emission factors. This model elucidates the synergistic relationships among the various stages of mining operations, equipment functionality, and carbon emission traceability.

The team employed the Sobol global sensitivity analysis method to quantitatively evaluate the model’s sensitivity to input variability. Their findings revealed that physical-mechanical parameters such as rock density, along with key operational factors like equipment power and loading capacity, directly influence the carbon emission profile of the mining process.

The case study conducted in Xinjiang demonstrated that seasonal climate variations, mining intensity fluctuations, and stripping ratios significantly influence overall carbon emission levels. Fuel combustion and electricity consumption were identified as the primary emission sources, with transportation and crushing operations constituting the predominant contributors to total emissions. Under equivalent production conditions, high-altitude environments generated an additional 43,183 tons of CO2 compared to conventional low-altitude regions.

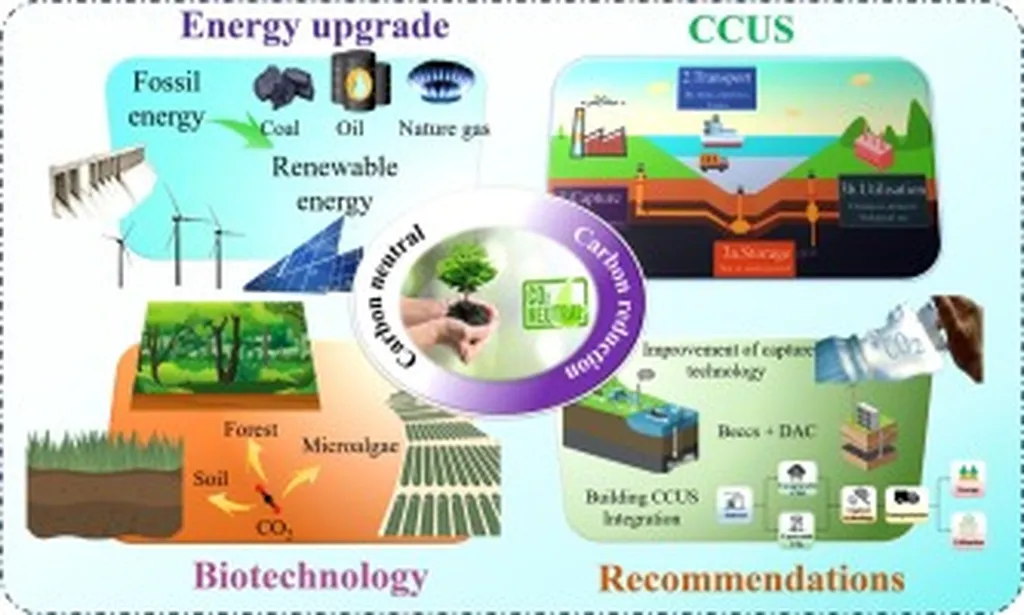

Li’s research offers a roadmap for low-carbon development strategies for high-altitude and cold-region mines. At the micro level, strategic measures must focus on optimizing extraction schedules, upgrading electrically powered mining equipment, and designing energy-efficient haulage routes. At the macro level, policy recommendations must emphasize promoting the substitution of fossil fuels with renewable energy sources, refining unified accounting standards, and implementing robust inspection and evaluation protocols.

This research, published in the Journal of Engineering Science (工程科学学报), provides a theoretical foundation and empirical reference for carbon accounting, energy conservation, consumption reduction, and the green transformation of high-altitude and cold-region open-pit metal mines. It offers a valuable reference for informing the mining sector’s green and low-carbon development aligning with the “dual carbon” objectives.

The implications of this research extend beyond the mining industry. As the world grapples with climate change and the need for sustainable practices, the insights gained from this study can inform broader industrial and policy decisions. By understanding the unique challenges and solutions in high-altitude and cold-region mining, we can better address the complexities of decarbonization across various sectors.

In the words of Li, “This study provides a valuable reference for the mining sector’s green and low-carbon development aligning with the ‘dual carbon’ objectives.” As we look to the future, the lessons learned from this research will undoubtedly shape the path towards a more sustainable and environmentally responsible mining industry.