In the heart of China’s coal country, a groundbreaking study led by Kang Li from the School of Mines at China University of Mining and Technology is set to revolutionize the way we approach ultra-close multi-seams mining. Published in the esteemed journal *Meitan xuebao* (translated to *Coal Science and Technology*), this research tackles one of the most pressing challenges in the coal mining industry: gas management in ultra-close coal seams.

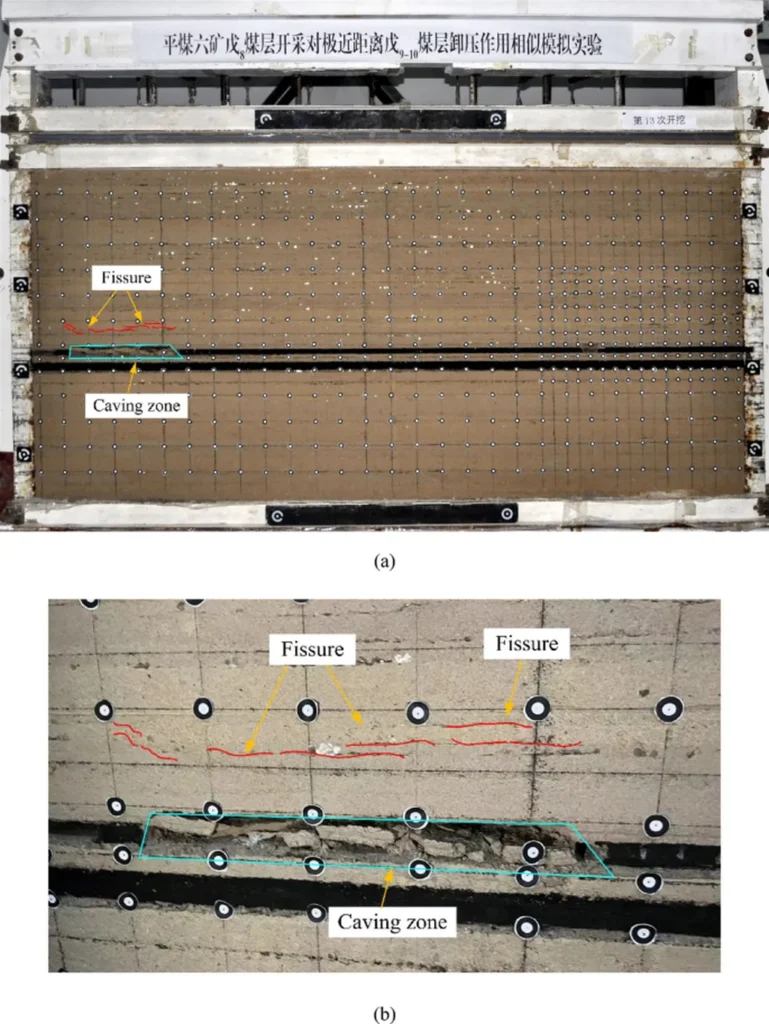

The study, conducted in the typical conditions of Shanxi Province’s ultra-close multi-seams mines, sheds light on the complex behavior of overburden rock and gas during pressure relief mining. “We’ve discovered that downward pressure relief mining causes the bottom rock layer to move towards the goaf, leading to a series of fascinating and challenging phenomena,” explains Li. This movement results in the expansion of the underlying coal rock layer, the development of mining-induced fractures, and the migration of methane gas, ultimately forming three distinct zones: the damaged gas-interflow zone, the floor pressure-relief zone, and the confined gas-adsorption zone.

The implications of this research are profound for the energy sector. In ultra-close multi-seams mining, the underlying coal seam often lies within the damaged gas-interflow zone. This means that gas can fully decompress and rapidly surge into the mining space along vertical fractures, posing a significant safety risk and potentially leading to gas exceeding the limit in the mining layer working face.

To combat this issue, Li and his team have developed a synergistic control technology dubbed “blocking-reducing-controlling.” This innovative approach involves three key strategies: gas extraction through high-level boreholes to block gas migration, precise regulation of air volume in the main and auxiliary intake airway Y-type ventilation to reduce gas accumulation, and buried pipe extraction in the goaf to control the gas flow field.

The results of this technology are impressive. High-level boreholes can achieve a maximum gas extraction volume of 1.34 m³/min, with optimal extraction occurring when the boreholes are 15−38 meters away from the working face. By maintaining an air volume ratio of 3:1 in the main and auxiliary intake airway, the gas emission rate is maximized. Furthermore, with an average negative pressure of 27 kPa, the amount of gas extracted from the buried pipes in the goaf reached 30 m³/min.

The practical applications of this research are vast. By implementing the “blocking-reducing-controlling” technology, mines can significantly reduce the gas volume fraction in critical areas, enhancing safety and operational efficiency. This technology has already demonstrated its effectiveness in industrial tests, reducing gas volume fraction in the tailentry and the goaf behind the supports by 73.0% and 64.6%, respectively, without exceeding the coal mine safety regulations in China.

As the energy sector continues to evolve, the insights gained from this research will be invaluable. By understanding the multi-field evolution laws of overburden rock in ultra-close multi-seams pressure relief mining, we can develop more effective and safer mining practices. This not only benefits the coal industry but also contributes to the broader energy sector by ensuring a more sustainable and secure supply of resources.

In the words of Kang Li, “This research represents a significant step forward in our understanding of ultra-close multi-seams mining. By applying the ‘blocking-reducing-controlling’ technology, we can enhance safety, improve efficiency, and ultimately, contribute to the sustainable development of the energy sector.” As we look to the future, the insights and innovations emerging from this study will undoubtedly shape the next generation of mining technologies and practices.