In a groundbreaking development poised to revolutionize the energy sector, researchers have made significant strides in advancing thixomolding technology for magnesium (Mg) alloys. This innovation promises to accelerate the adoption of lightweight, high-performance materials in manufacturing, with profound implications for energy efficiency and sustainability.

At the forefront of this research is Minjie Huang, a distinguished professor affiliated with the School of Materials Science and Engineering at Harbin Institute of Technology and the School of Mechanical Engineering and Automation at Fuzhou University. Huang’s team has published a comprehensive review in the Journal of Magnesium and Alloys, titled “Review of development and progress on thixomolding technology of magnesium alloys.” This work offers an in-depth look at the progress and potential of thixomolding technology, a process that could transform the production of structural components across various industries.

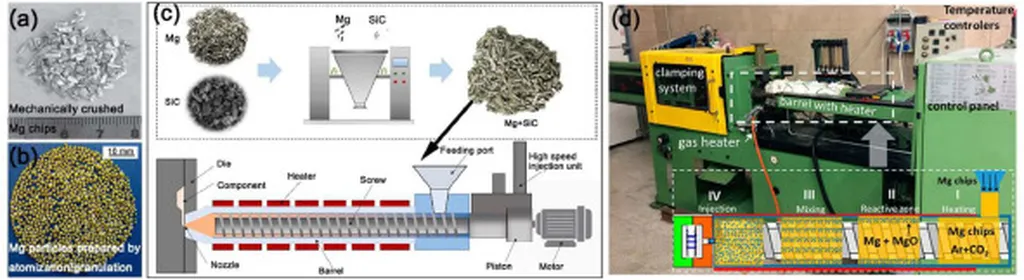

Thixomolding, a semi-solid metal processing technique, combines the best aspects of injection molding and die casting. It allows for the creation of complex, high-strength magnesium alloy components with exceptional precision and efficiency. “This technology is a game-changer,” Huang explains. “It enables the production of lightweight, high-performance parts that are crucial for industries aiming to reduce energy consumption and environmental impact.”

The research highlights several key areas of advancement. Firstly, it explores the materials used in thixomolding, including magnesium alloys and magnesium-based composites, which offer superior strength-to-weight ratios and enhanced durability. The study also delves into the thixomolding process itself, examining process characteristics, the influence of process parameters, common defects, and optimization strategies.

One of the most compelling aspects of the research is its focus on the properties of thixomolded magnesium alloys and composites. These materials exhibit exceptional mechanical properties, making them ideal for applications in the automotive, aerospace, and energy sectors. “The potential for energy savings is immense,” Huang notes. “Lighter components mean lighter vehicles and machinery, which in turn reduce fuel consumption and emissions.”

The study also reviews the development of thixomolding machines and equipment units, highlighting the progress towards advanced and large-scale thixomolding technologies. This evolution is critical for meeting the growing demand for high-quality, lightweight components in various industries.

Perhaps most importantly, the research summarizes the current industrial applications of magnesium alloy thixomolding technology, providing real-world examples of successful implementations. These case studies demonstrate the technology’s viability and its potential to drive innovation in manufacturing.

Looking ahead, Huang and his team propose several perspectives on the future of magnesium alloy thixomolding technology. These include the development of specialized magnesium alloys, overcoming technological barriers, advancing thixomolding equipment, cultivating talent, and promoting sustainable development.

The implications for the energy sector are profound. As industries strive to meet increasingly stringent environmental regulations and consumer demand for fuel-efficient products, the adoption of lightweight materials like magnesium alloys could play a pivotal role. “This technology is not just about improving manufacturing processes; it’s about shaping the future of sustainable energy,” Huang concludes.

Published in the Journal of Magnesium and Alloys, this research offers a roadmap for the future of thixomolding technology, highlighting its potential to revolutionize manufacturing and drive progress towards a more sustainable and energy-efficient future. As industries continue to explore the benefits of lightweight materials, the insights provided by Huang and his team will be invaluable in guiding the development of next-generation technologies.