In a groundbreaking development poised to revolutionize the aerospace and defense industries, researchers have introduced a novel machining technique that promises to significantly enhance the production of nickel-based superalloy honeycomb composites (NBSHC). This innovation, spearheaded by Haihang Wang from the State Key Laboratory of Mechanical System and Vibration at Shanghai Jiao Tong University, challenges the traditional grinding methods, offering a more efficient and higher-quality alternative.

Nickel-based superalloy honeycomb composites are celebrated for their low density, exceptional high-temperature resistance, and superior specific strength. These properties make them indispensable in sectors where performance under extreme conditions is paramount. However, the conventional grinding process, while effective, has limitations in terms of efficiency and quality. Enter disc-cutter milling, a technique that not only addresses these shortcomings but also opens new avenues for advancement.

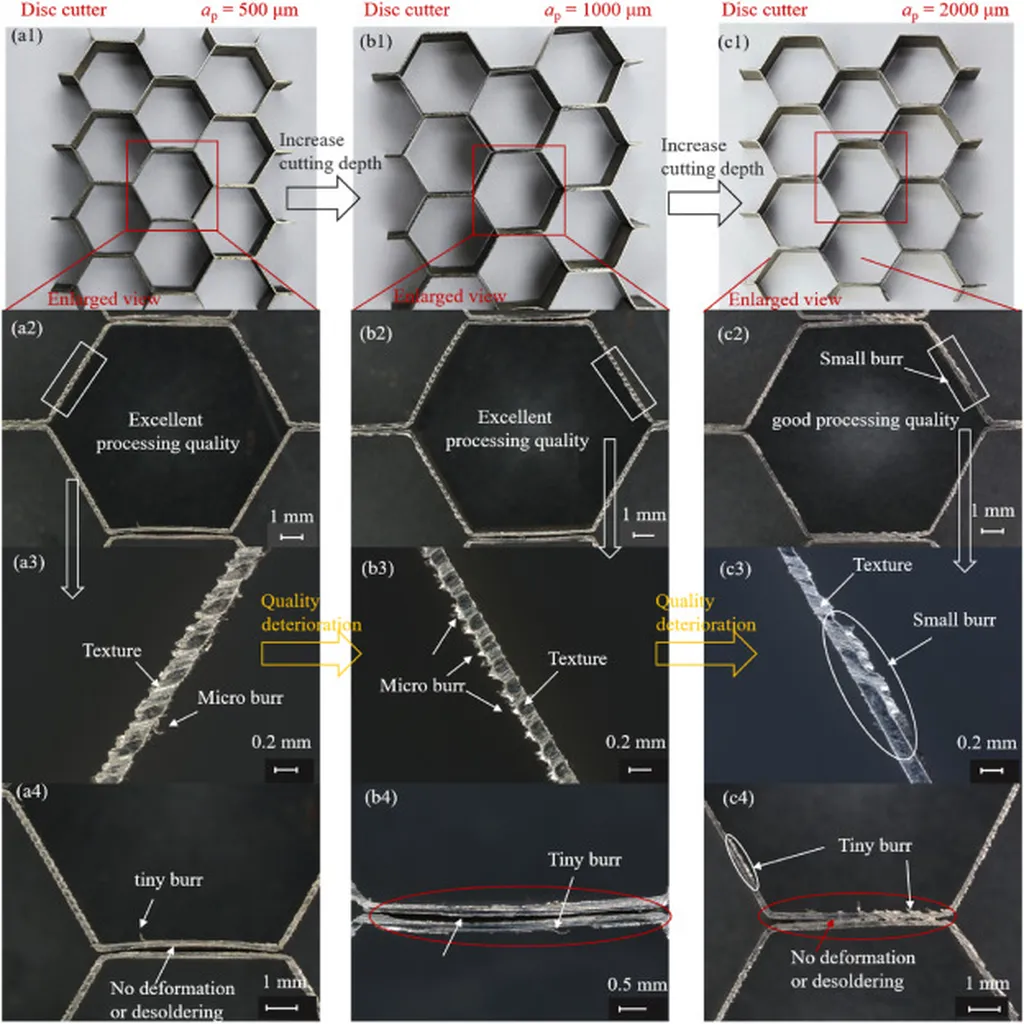

“The cutting forces were minimized, resulting in lower temperatures and thus reducing the region of deformation and thermal softening effects,” explained Wang. This reduction in cutting forces is a game-changer, as it facilitates easier material removal and chip formation. The material removal process occurs through cutting, with a shear surface forming the contact zone where stress, energy, and plastic strain are concentrated. This concentration of forces and energy minimizes the occurrence of severe defects, ensuring that the machining quality meets practical requirements.

The implications of this research are profound. By replacing traditional grinding with disc-cutter milling, the efficiency of machining NBSHC has been increased by a factor of 33. This dramatic improvement in efficiency can lead to significant cost savings and production enhancements in the aerospace and defense sectors. The reduced defect rate also ensures higher quality end-products, which is crucial in industries where precision and reliability are non-negotiable.

The study, published in the *Journal of Materials Research and Technology* (translated from Chinese as “Materials Research and Technology Journal”), provides a comprehensive analysis of the cutting force, temperature, plastic deformation, and defect behavior involved in the material removal process. Through a combination of experiments and simulations, the researchers have unveiled the intricate mechanisms that make disc-cutter milling a superior alternative to grinding.

This research not only addresses immediate industrial needs but also paves the way for future developments. As Haihang Wang and his team continue to explore the potential of disc-cutter milling, the aerospace and defense industries can look forward to even more innovative solutions that enhance efficiency, quality, and cost-effectiveness. The journey towards optimizing the production of nickel-based superalloy honeycomb composites has taken a significant leap forward, and the future looks brighter than ever.