In the quest to enhance the performance of materials in extreme environments, a recent study has shed light on the critical role of filler metals in welding 9% nickel steel, a material widely used in cryogenic applications such as liquefied natural gas (LNG) storage and transportation. The research, led by Jooyong Cheon from the Department of Materials Science and Engineering at Pusan National University and the Smart Forming Process Group at the Korea Institute of Industrial Technology, delves into the effects of different nickel-based filler metals on the microstructure and cryogenic impact toughness of flux-cored arc welding (FCAW) welds.

The study, published in the Journal of Materials Research and Technology (translated from Spanish as “Journal of Materials Research and Technology”), evaluated three Ni-based filler metals—Alloy 625, 609, and 709—under identical welding conditions to isolate the effects of filler composition. The findings revealed significant variations in weld bead geometry, microstructure, and mechanical properties.

Alloy 625, for instance, produced the tallest weld bead, while Alloy 609 exhibited the greatest penetration. “These differences are attributed to variations in thermal conductivity and melt fluidity,” explained Cheon. The weld metals displayed dendritic structures with varying degrees of interdendritic segregation, which played a crucial role in their mechanical performance.

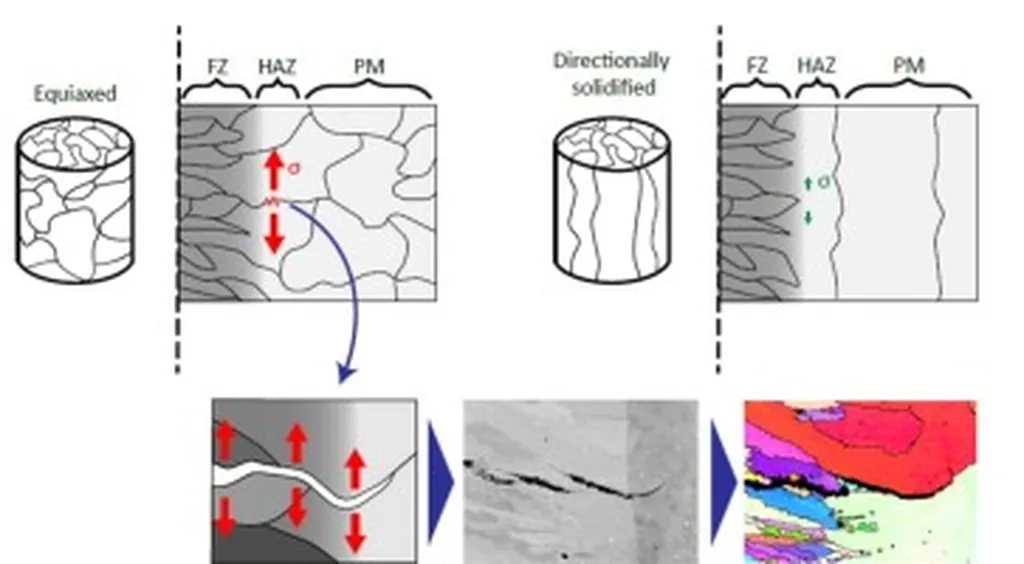

Charpy impact tests conducted at -196°C showed that Alloy 625 achieved the highest impact toughness in the weld metal, whereas Alloy 709 exhibited superior toughness in the heat-affected zone (HAZ). Electron backscatter diffraction (EBSD) analysis provided further insights into the microstructural characteristics. Alloy 625 maintained high phase stability with a low high-angle grain boundary (HAGB) fraction, while Alloy 709 exhibited coarse but uniform grains and a moderate HAGB fraction, effectively suppressing strain localization and enhancing cryogenic toughness.

The implications of this research are significant for the energy sector, particularly in applications involving cryogenic conditions. “Understanding the role of filler metals in tailoring weld microstructure and optimizing mechanical performance is crucial for the development of robust and reliable structures,” Cheon noted. This study provides new insights into filler optimization strategies for cryogenic applications, potentially shaping future developments in materials science and engineering.

As the demand for LNG and other cryogenic applications continues to grow, the findings from this research could pave the way for improved welding practices and material selection, ultimately enhancing the safety and efficiency of energy infrastructure. The study’s systematic investigation of multiple Ni-based filler metals offers a valuable resource for engineers and researchers seeking to optimize weld performance in extreme environments.