Weir, a global mining-technology firm, has unveiled a revamped line of Enduron jaw and cone crushers, developed in close partnership with customers to address their most pressing operational challenges. This customer-driven design approach has resulted in enhancements that prioritize safety, productivity, maintenance ease, and sustainability.

The updated Enduron jaw crushers now feature a redesigned hydraulic power unit (HPU) that enables true push-button closed-side setting (CSS) adjustments. This innovation eliminates the need for manual intervention, significantly reducing safety risks for operators and maintenance crews. The new HPU also maintains consistent retraction-spring tension across the full wear range of the jaw dies, enhancing reliability and user-friendliness. Additionally, optimized motor sizing and a right-sized oil tank lower the HPU’s CO₂ output, shrinking its environmental footprint.

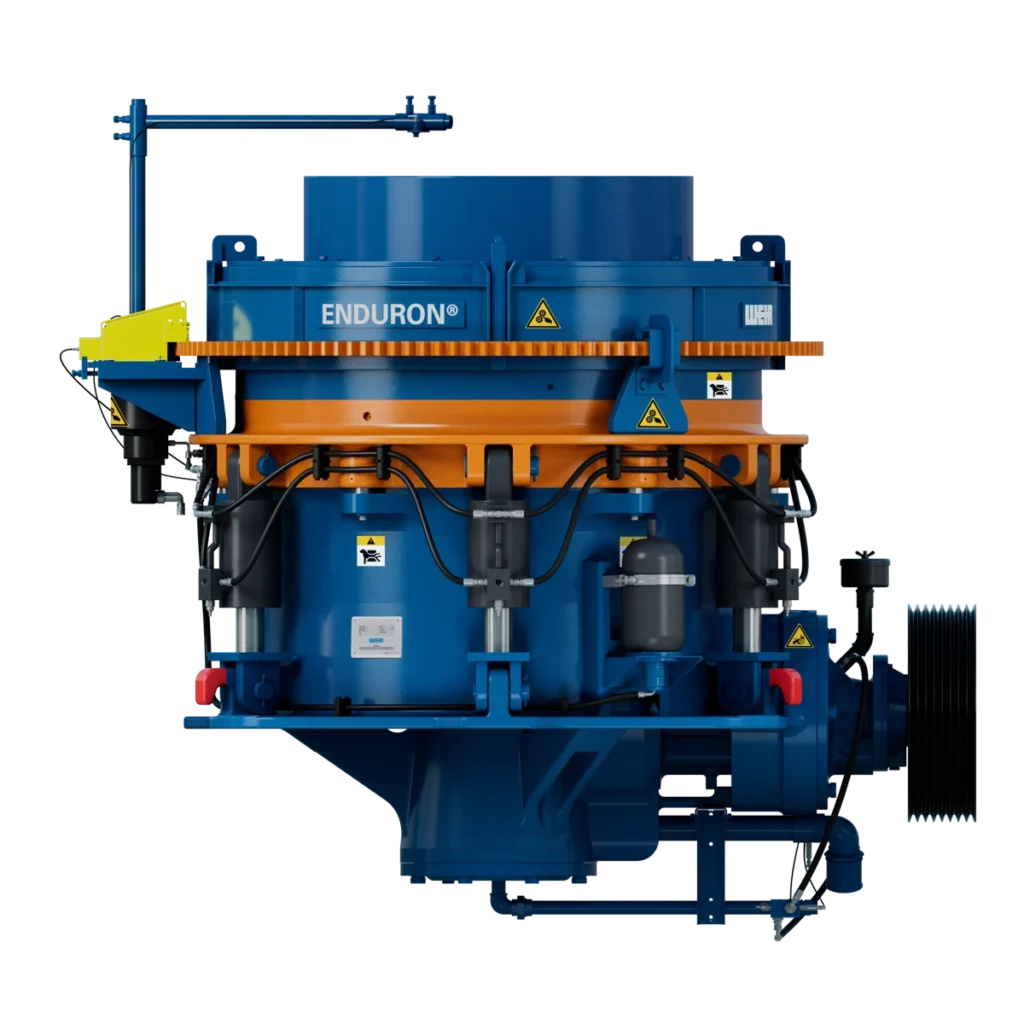

To minimize downtime and extend run times, the entire Enduron jaw range now ships with Esco wear parts. These proven components extend wear life, reduce maintenance frequency, increase equipment availability, and lower operating costs. The upgraded Enduron cone crushers also feature Esco wear liners and a redesigned hydraulic and lubrication power unit (H/LPU). The compact, plug-and-play H/LPU simplifies installation and reduces environmental impact, making it ideal for sites that prioritize faster setup and a smaller footprint.

Weir has also enhanced automation across the cone range. IO-link digital sensors paired with Siemens PLC hardware improve integration and fault-finding, while a new human-machine interface (HMI) eases servicing and streamlines control. The new suite includes Enduron ET jaw crushers and both EP fixed-shaft and EC live-shaft cone models, providing operators with options to match equipment to site-specific needs.

As the mining industry shifts toward greater energy efficiency and lower emissions, these crushers integrate seamlessly with existing Enduron screens and high-pressure grinding rolls (HPGRs) to create full flowsheets that cut energy use and boost overall performance. Magnus Skorvald, global product manager of crushers at Weir, emphasized the importance of customer feedback in shaping the new range. “We’ve listened closely to our customers and designed this range to meet their evolving needs. From safety and sustainability to ease of installation and maintenance, every feature is built to deliver real value on site.”

Whether operators choose to retrofit or install new plants, the expanded Enduron comminution family aims to help them run smarter, safer, and more sustainably. This development underscores a broader trend in the mining industry toward collaborative innovation, where equipment manufacturers and end-users work together to address real-world challenges. As mining operations face increasing pressure to improve efficiency and reduce environmental impact, such advancements are likely to shape the future of the sector. The integration of digital technologies and a focus on sustainability are set to become standard, driving the industry toward a more productive and eco-conscious future.