In a groundbreaking study published in the Journal of Materials Research and Technology (Revista de Materiales e Tecnología in English), researchers have uncovered significant insights into the functional properties of BaTi0.90Hf0.10O3 ceramics, which could revolutionize energy storage technologies. The lead author, Elena Mirabela Soare from the Institute of Physical Chemistry “Ilie Murgulescu” and the National University of Science and Technology Politehnica Bucharest, delved into the intricate world of nanostructured ceramics, revealing how grain size and sintering methods can dramatically influence material performance.

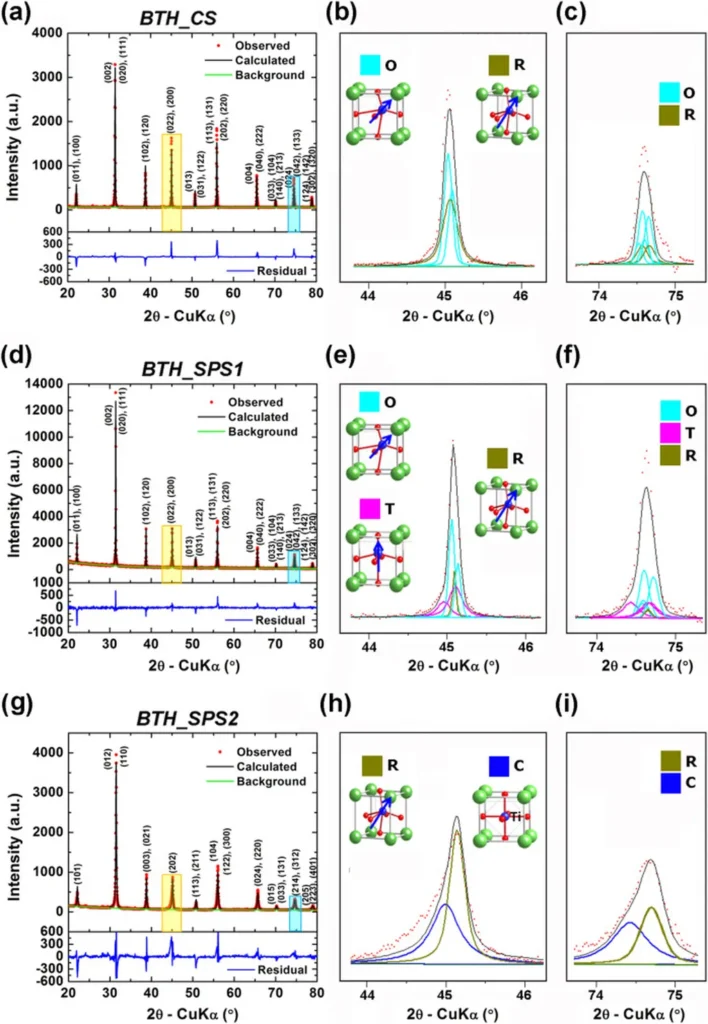

The research focused on the effects of grain size on the functional properties of BaTi0.90Hf0.10O3 ceramics, which exhibit phase coexistence around room temperature. By employing different sintering strategies, including the fast field-assisted Spark Plasma Sintering (SPS) and conventional sintering, Soare and her team were able to produce ceramics with grain sizes ranging from 3.7 to 0.07 micrometers. This meticulous approach allowed them to observe the nuanced behavior of these materials under varying conditions.

One of the most compelling findings was the impact of grain size reduction on the Curie temperature and the ferroelectric-to-paraelectric phase transition. As the grain size decreased, the Curie temperature slightly lowered, and the transition became more diffuse. This phenomenon was accompanied by a decrease in permittivity maxima and dielectric losses, indicating a shift towards a ferroelectric-relaxor crossover. “The decrease in grain size not only alters the structural modifications but also enhances the energy storage efficiency,” Soare explained, highlighting the potential commercial implications for the energy sector.

The study also revealed that the fast sintering method induced strain-stress fields, which, in turn, influenced the stability of different polymorphs within the ceramics. Landau-based calculations confirmed these experimental observations, providing a theoretical framework for understanding the structural and Raman analyses. “The interplay between grain size, sintering method, and internal stress fields opens up new avenues for tailoring the properties of these ceramics,” Soare noted, emphasizing the importance of these findings for future material design.

The implications of this research are far-reaching, particularly for the energy sector. The enhanced energy storage efficiency observed in nanostructured ceramics could lead to the development of more efficient and reliable energy storage devices. This could be a game-changer for renewable energy technologies, which often require robust and efficient storage solutions to manage intermittent power generation.

Moreover, the insights gained from this study could pave the way for the development of new materials with tailored properties for specific applications. By understanding the intricate relationship between grain size, sintering methods, and internal stress fields, researchers can design materials that meet the exacting demands of various industries, from electronics to aerospace.

As the world continues to grapple with the challenges of climate change and the need for sustainable energy solutions, research like Soare’s offers a beacon of hope. By pushing the boundaries of material science, we can unlock new possibilities for a greener and more efficient future. The findings published in the Journal of Materials Research and Technology not only advance our understanding of BaTi0.90Hf0.10O3 ceramics but also set the stage for future innovations in the field of energy storage and beyond.